The humble flag, often overlooked, yet an essential symbol of national, regional or organizational identity. If you’ve ever watched one fluttering in the breeze and wondered just how these vivid symbols of pride and unity come into existence, you’re not alone. Flags are a tangible reflection of culture, history, and brand identity – they are more than just a piece of fabric fluttering in the wind. The process of making flags, much like the stories they represent, involves intricate detail and precision. In this blog post, we will pull back the curtain on the fascinating world of flag making. Let’s dive into the process that turns simple cloth into a powerful emblem.

(Basic Components of a Flag)

Flags, being a symbol of identity, are often meticulously designed and constructed. Conceptually, a flag is comprised of three main elements – the field, the emblems, and the colors.

The field refers to the predominant background color of the flag.

Emblems or symbols are usually superimposed onto the field. These can range from simple geometric shapes to detailed representations of plants, animals, or even landscapes, depending on what the flag is meant to represent.

Color holds their special significance in flags. It’s interesting to note that meaning of colors can vary largely from culture to culture. For instance, in Western cultures, blue typically represents freedom, while in many Eastern cultures, it signifies immortality.

In creating a flag, each of these elements must be carefully selected to accurately convey the intended message. They are the basic components that contribute to the overall visual impact and significance of a flag.

(Understanding Flag-Making Materials)

Understanding the intricacies of flag-making involves taking a closer look at the materials used in their manufacture.

Flags are usually made from durable, light, and weather-resistant fabric to withstand being flown outdoors. This often includes materials such as polyester, nylon, and cotton.

Polyester is used for its toughness, making it especially suitable for harsh weather conditions. Nylon, on the other hand, is appreciated for its impressive resilience, lightweight and its ability to dry quickly after rainfall.

Cotton is less prevalent in flag production due to its less resilient nature, but it provides a classic, rich appearance. The choice of fabric is highly dependant on the intended use of the flag, with the material influencing not only the flag’s durability but also how it flies in the wind.

(Step 1: Designing the Flag)

Creating a flag is an intricate process that begins with a well-thought-out design. The flag’s design is often a symbolic representation of the country, organization, or event it represents.

To conceive a flag design, it requires graphic art skills, creativity, and a clear understanding of the message or values the flag is meant to portray. The initial design is often drawn on paper or created digitally using graphic design software like Adobe Illustrator.

Colors must be chosen carefully, considering not only their aesthetic appeal but also the emotions and notions they signify.

Shapes and emblems used also hold significant importance. The design shouldn’t be overcrowded, balance and simplicity are key.

Once the design is completed and approved, it’s then transferred onto fabric. That’s when the actual manufacturing begins. But remember, a visually appealing, meaningful design is pivotal to producing a flag that stands out.

(Step 2: Selecting the Right Fabric)

The second step in the flag-making process is selecting the right fabric. This is crucial as it directly affects the durability and aesthetics of the flag. Normally, fabrics like nylon, polyester, and cotton are used, each with its own unique advantages.

Nylon, for instance, is lightweight and flies well in light winds, making it ideal for outdoor flags. Polyester, on the other hand, is heavier and more durable, suitable for inclement weather conditions. Cotton provides a traditional look, best suited for indoor or ceremonial use.

Once a fabric is decided upon, the desired quantity is sourced from trustworthy suppliers, ensuring consistent quality. Color check is also conducted to ascertain the correct shade that matches the original flag design. This early emphasis on quality materials sets the stage for a worthwhile end product.

(Step 3: Dyeing Process in Flag Making)

In the third stage of flag making, we enter the intricate realm of the dyeing process.

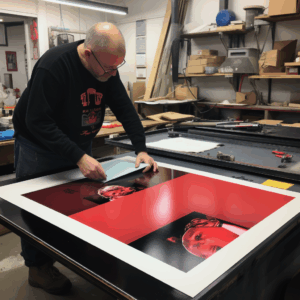

Here, the pre-determined design is brought to life with vibrant hues. The dyeing process is mainly done using screen printing or digital printing, based on the complexity and color variation of the design.

For screen printing, each color is applied separately through high-pressure hoses onto a mesh screen, then transferred on to the fabric. Meanwhile, in digital printing, a computer-driven printer directly sprays the dye onto the pre-cut fabric.

High-quality, fade resistant dyes are used to ensure color longevity. The material is then heat treated to fix the color and increase its durability.

This methodical dyeing process not only gives the flag its visual appeal but also emphasizes its symbolic importance.

(Step 4: Cutting, Sewing and Finishing)

After the dyeing process comes the fourth stage – cutting, sewing, and finishing. This step is crucial to shape the flag and strengthen its ends for durability.

The fabric is laid flat for cutting. The dimensions must precisely match the intended design. This step requires skilled workmanship for high precision.

The cut pieces are then sewn together. This would typically involve hemming, which serves to prevent fraying. The expert seamstress must work meticulously to ensure a seamless appearance.

Finally, the flag undergoes a finishing process. It could be pressed to get rid of any wrinkles, and hardware like grommets are often added at this stage.

This contributed to the overall quality and longevity of the flag. Every step, especially cutting, sewing, and finishing, needs a certain level of expertise, guaranteeing a top-quality finished product. Each flag becomes a symbol of pride and identity, thus the necessity for perfection.

(Industrial Process of Flag Production)

In the industrial production of flags, the process begins with design. Once a design is approved, it’s transformed into digital format and then sent to a computerized printing machine. Here, vibrant inks are applied onto high-quality fabric, usually nylon or polyester, in a process known as dye-sublimation.

Following this, the fabric is heat-set to seal the colors and ensure they remain fast during all weather conditions. Next, the fabric is trimmed and sewn into the shape of a flag using industrial sewing machines. Extra-durable thread is used for lasting quality.

Finally, the flag is completed by adding grommets or a pole sleeve for flying purposes. After a thorough inspection, the flag is packed and shipped, ready to be hoisted high and represent its intended identity. From design concept to the finished product, flag making is a meticulous process that demands precision and expertise.

(Handmade Flags Vs. Machine-Made Flags)

Handmade and machine-made flags differ greatly in their crafting process. The former often boasts a unique, artisanal feel. Each cut, stitch, and detail represent the dedication of a skilled craftsperson. These flags can exhibit an unbeatable quality wedded to timelessness and personal touch.

Conversely, Machine-made flags are typified by efficiency and uniform precision. Modern equipment allows for high-volume production, making these flags more cost-effective and faster to produce. The finished product often appears flawless, with every stripe or emblem identical due to machine precision.

Both types have their distinct appeal. It’s a matter of preference whether the personal craftsmanship of handmade flags outweighs the uniformity and efficiency of machine-made counterparts.

Previous reading

Previous reading